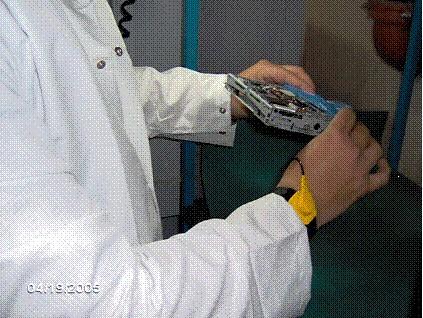

Sorting and Rework (On site or SMR Warehouse)

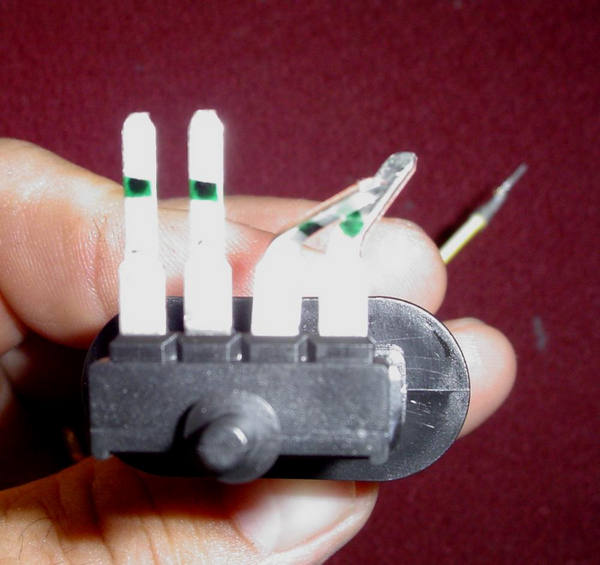

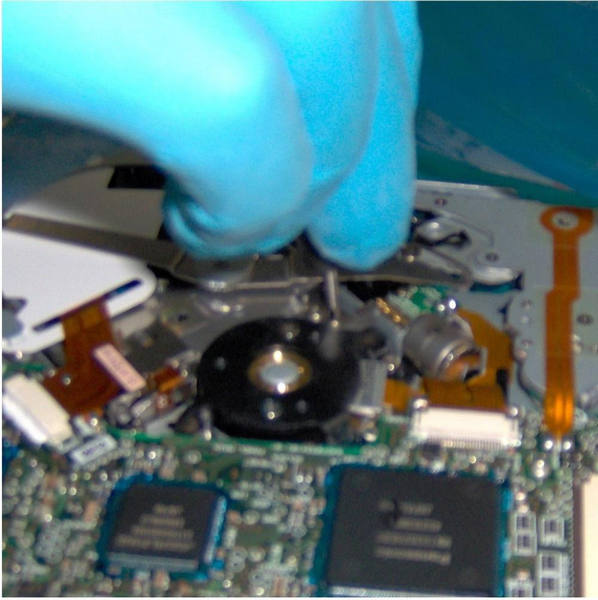

SMR has proven sorting experience on a variety of process and products and wide list of parts such as:

All rework operations are performed by using the single piece flow concept to avoid matetrial over-handling and damages.

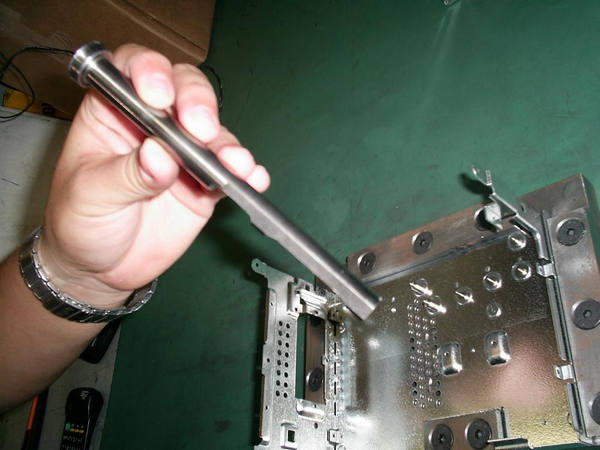

Rework can be done either with special dedicated tooling owned by customer or SMR. Separated charges may apply if dedicated tooling owned by SMR.

Rework operations can be performed either on Customer site or SMR warehouse.

All rework operations are well documented in work instructions and visual aids (as required).